Bold, Daring

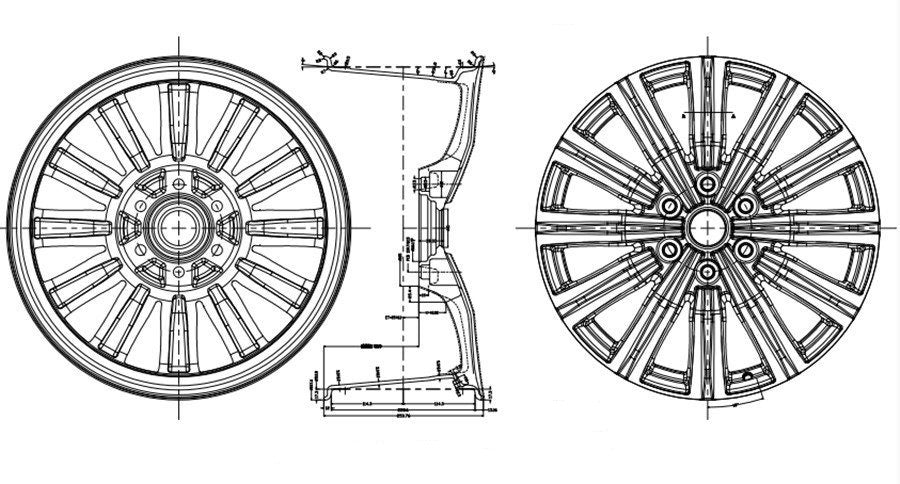

TRULY 100% Custom Wheels

We don't pretend to have "custom wheels"...

BE EXTRA- ORDINARY

We can manufacture three-piece wheels in any style perfectly matched for your build. Have big breaks or need wild offsets? With GTG Wheels you get exactly what you want.

SHOP NOW →